Polymer brushes have gained significant attention and relevancy due to their versatile ability to modify surfaces. Polymer brush bioconjugation to interfaces increases surface durability and allows for more dynamic interaction and responses to the environment. The application of polymer brushes first gained popularity in the 1950s, after the grafting of polymer molecules to colloidal particles was found to prevent flocculation. Since then, the application of polymer brushes has extended to areas in optoelectronics, biomineralization, medical diagnosis, drug delivery, and more. In this article, we will discuss in detail the different methods and applications of polymer brush bioconjugation.

Polymer brush bioconjugation tethers the functional groups of the polymer to a target substrate through “grafting to”, “grafting from” and “grafting through” methods. Bioconjugation of polymer brushes can be used for drug delivery, biosensing, and antimicrobial surface engineering.

What Is A Polymer Brush?

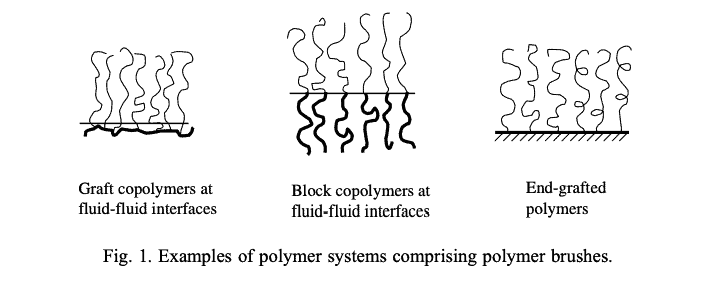

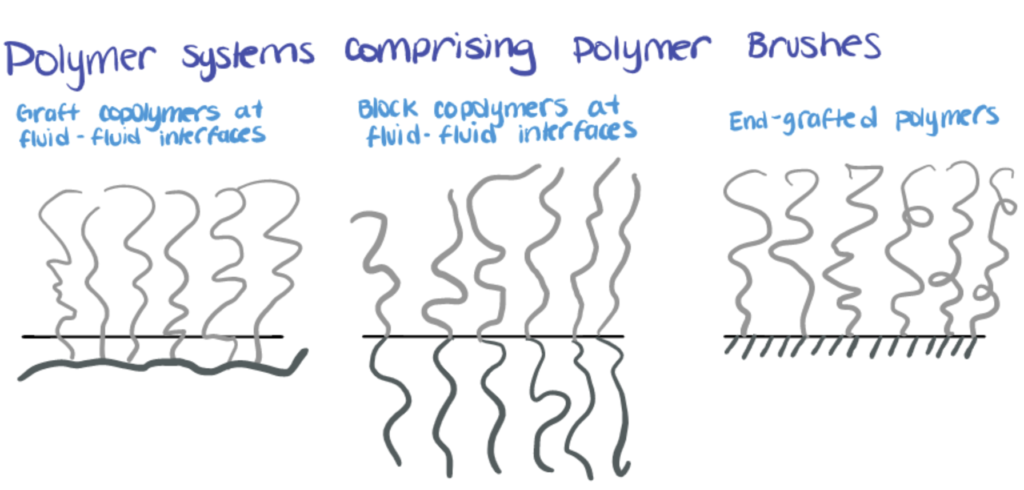

Polymer brushes contain polymer chains bioconjugated to other polymers, solid or liquid substrates, or at the interface between different states of matter, and possess different functions depending on surface properties.

Polymer brushes are macromolecular structures with polymer chains tethered to either another polymer chain, a planar, or a cylindrical solid through covalent or non-covalent bonds. It may also be on a solid substrate surface, an interface between two liquids, or an interface between liquid and air (Feng & Huang, 2018; Zhao & Brittain, 2000). Like other bioconjugation to surfaces applications, different properties of the polymer chains introduce new functionalities and properties to its tethered surfaces. The high density of polymer brush conjugation results in the chains stretching away from the surface, hence forming “brushes”.

Polymer Brush Bioconjugation Methods

Bioconjugation of polymer brushes to different surfaces can be achieved through a “grafting to”, “grating from”, and “grafting through” techniques via cell adhesion peptides, polylactic acid, and copper-assisted click chemistry, respectively.

As mentioned above, the main synthesis approach of polymer brushes includes “grafting to”, “grafting from” and “grafting through” approaches (Li & Pester, 2020).

The “grafting to” approach attaches a previously synthesized polymer chain to a surface. This works best with lower molecular weight polymers because of the steric hindrance from pre-synthesized polymers that may block reactive sites. Even though the resulting grafting density is lower, it ensures precise polymer characterization before surface deposition.

The “grafting from” approach initiates the growth of the polymer brushes directly from a surface. The surface needs to be coated with initiators, followed by diffusion of small molecules that results in a growing polymer chain. This approach offers higher grafting density but requires a more controlled environment to ensure final polymer characterization.

The “grafting through” approach attaches polymers through polymerization in the presence of a substrate with tethered monomers. It is one of the simplest ways to design copolymers.

Below are 3 detailed methods used for the conjugation of polymer brushes.

Method 1. Bioconjugation Using “Grafting To” Method

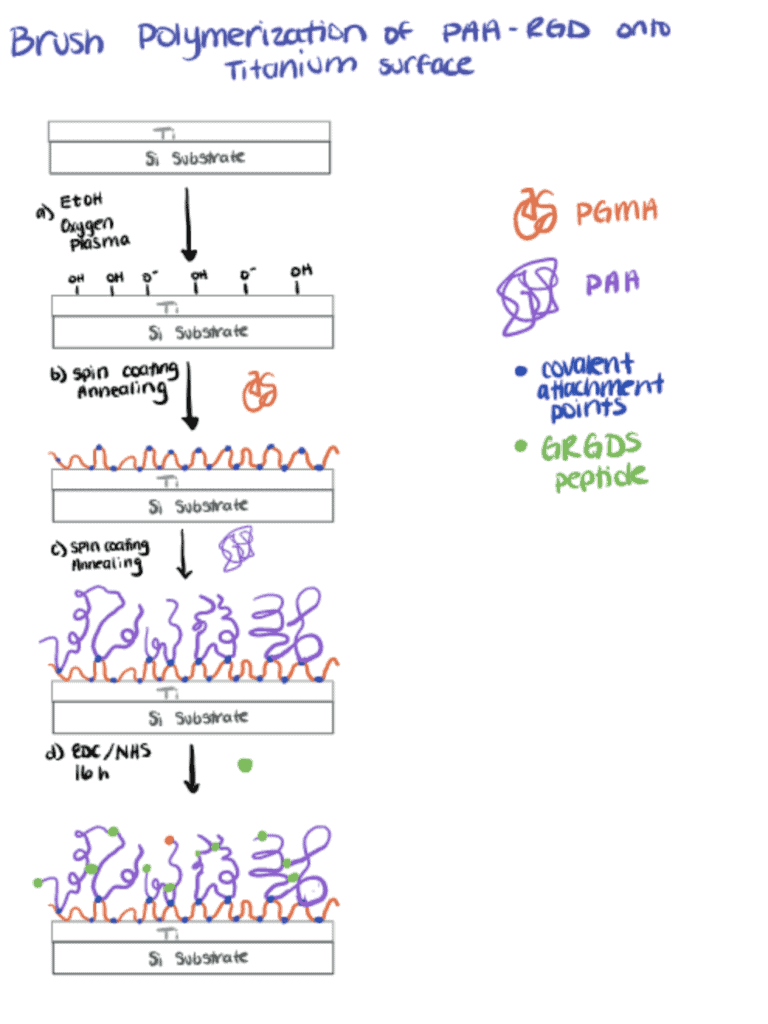

An example of a “grafting to” method is illustrated in the study of poly(acrylic acid) (PAA) brushes with cell adhesion peptides (RGD) onto a titanium surface (Rosenthal et al., 2018).

PAA brushes are weak polyelectrolytes that are known for their pH-dependent deprotonation of carboxyl groups. It is grafted as “pseudo” brushes with multiple covalent attachment points in one chain onto the surface of the substrate. The carboxyl groups of PAA also allow for the attachment of RGD as functional groups onto the polymer brushes. The PAA-RGD brush polymerized on a Titanium surface allows for cell adhesion with biocompatibility.

Step 1. Deposit titaniumPellets onto Si-water Substrates

Electron beam evaporation of titanium pellets onto Si water substrates in an ultra-high deposition vacuum chamber.

Step 2. Transfer PAA Brushes onto Titanium surface

PGMA is spin-coated and annealed on top of the titanium surface, resulting in a thin reactive anchoring layer with an epoxy group. PAA solution is spin-coated onto the grafted PGMA layer under vacuum. The epoxy groups of PGMA react with the COOH groups along the chain of PAA, leading to the grafting of PAA chains in loops via ester bonds.

Step 3. Attach RGD Peptides To PAA Brushes

RGD-containing peptides are covalently bound to the PAA brushes on the Titanium surface through activation of the PAA carboxyl group with EDC and NHS to result in the conjugation of the COOH groups to the amines of the peptides, which is comparable to NHS-ester bioconjugation protocols.

Method 2. Bioconjugation Using “Grafting From” Method

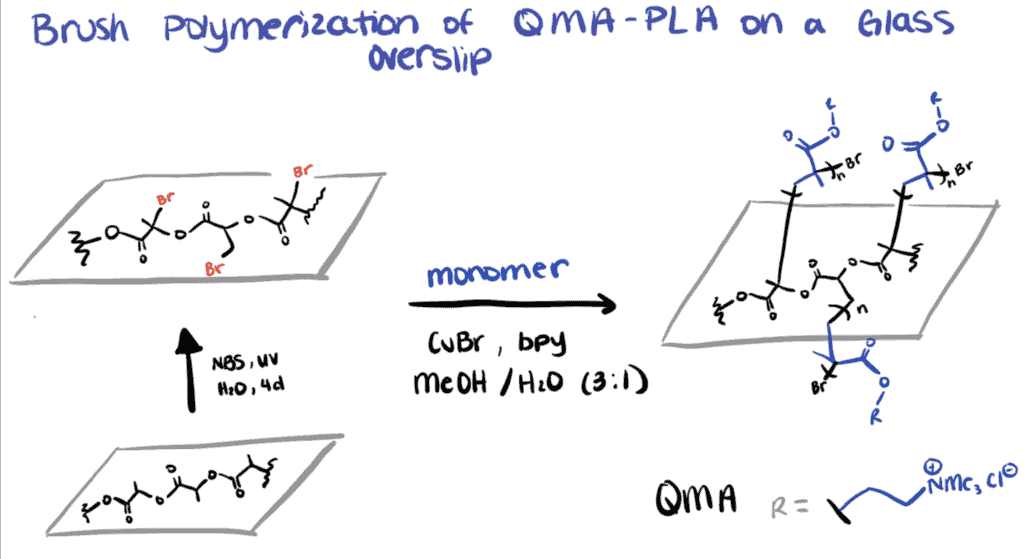

PLA (polylactic acid) is another popular polymer brush, it is biocompatible and biodegradable, which makes it an excellent surface layer for devices such as sutures, stents, and scaffolds for bone regeneration. However, the hydrophobicity of PLA results in biofouling that can lead to infection.

There have been efforts in tackling the problem through grafting bacteria-resistant polymers onto PLA, however, the approaches involve multistep synthesis (Kalekar et al., 2022). We will be discussing methods utilized by Kalekar et al. (2022) that offer a more efficient strategy for modifying PLA surfaces with quaternary ammonium methacrylate (QMA) on glass surfaces. QMA displays antimicrobial functions. The “grafting from” approach used in this study results in higher density polymer brushes compared to previous studies of “grafting to” approaches using PLA.

Step 1. Prepare PLA Film

PLA in Ch2Cl2 is drop casted onto a glass coverslip. The PLA film is then treated with N-bromosuccinimide (NBS) in water under UV irradiation. This results in the incorporation of up to 3.7% bromide on the surface of PLA.

Step 2. Perform SI-ATRP On The Brominated Pla Surface

The brominated PLA surface serves as a macroinitiator for SI-ATRP of QMA chloride. The SI-ATRP reaction is carried out in the presence of CuBr and bpy.

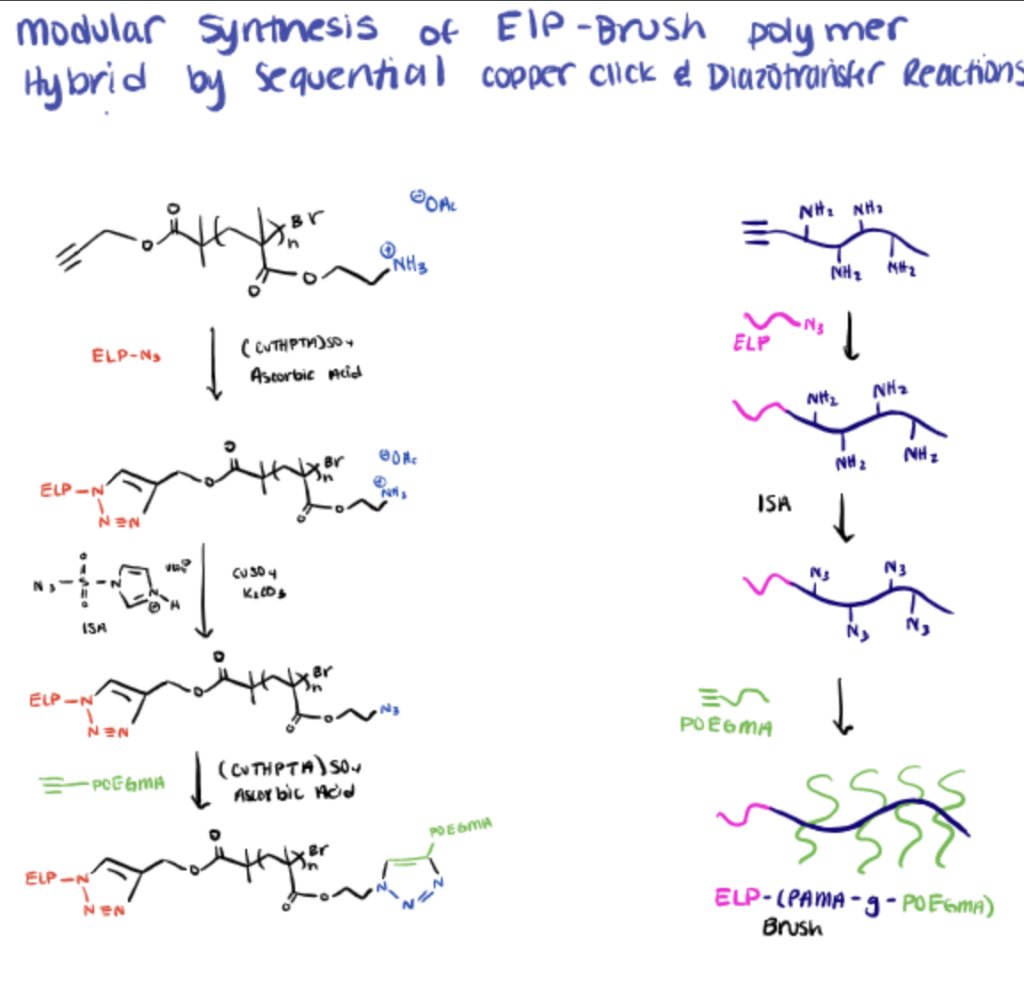

Method 3. Bioconjugation Using Click Chemistry

Click chemistry is widely used in bioconjugation due to its high conjugation efficiency, fast reaction time, and high functional group tolerance. Below, we will be discussing the use of copper-assisted click chemistry to synthesize brush polymer protein hybrids (Navarro et al., 2018).

Step 1. Create Polymer Backbone

The amine-containing monomers of P(AMA- co-HEMA) serve as handles to introduce azide groups for the grafting of alkyne-terminated polymer bristles POEGMA. PHEMA is copolymerized into the backbone.

Step 2. Prepare ELP For Bristle Synthesis

Prepare ELP for conjugation by introducing azide groups through diazotransfer with ISA. The addition of one polymer brush to each protein is controlled because the protein lacks lysine, therefore only its N-terminus is available for diazo transfer.

AGET ATRP mechanism is used to synthesize POEGMA bristles with alkyne terminals. AGET ATRP has been proven to be effective in synthesizing high molecular weight backbone polymers

Step 3. Perform Copper-Assisted Click Chemistry

Lastly, copper-assisted click chemistry is used for the final polymer brush assembly. TIPS is used during the reaction as a protecting group to prevent side reactions during polymerization.

Applications Of Polymer Brushes

Polymer brush bioconjugation has applications as drug delivery carriers, biosensors, and antimicrobial bioconjugates.

There is a broad range of applications of polymer brushes due to the wide varieties of polymers that can be utilized, the different types of surfaces they can be grafted on, and the different mediums they can be in.

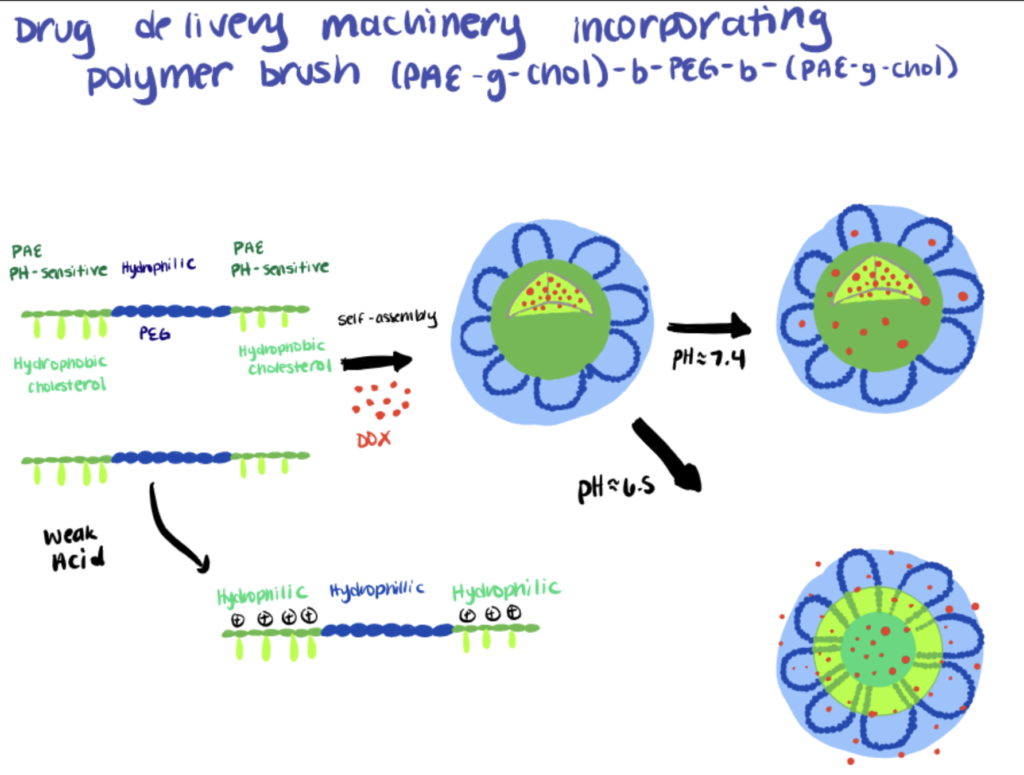

Application 1. Drug Delivery

Different characteristics of polymers, such as pH sensitivity, biocompatibility, and low toxicity improve methods of drug delivery.

Self-assembled polymeric micelles can be used as hydrophobic anticancer drug delivery carriers (Huang et al., 2017). A triblock polymer brush (PAE-g-Chol)-b-PEG-b-(PAE-g-Chol) with pH sensitivity is designed through Michael-type step polymerization and acylation reactions. The sharp pH sensitivity of the polymer brush comes from the amino groups of the PAE, which transforms it from being hydrophobic to hydrophilic. The sharp pH sensitivity allows for a more controlled release of drugs. The incorporation of cholesterol onto the polymeric micelle also enhances drug LC and the overall stability of the system. Brush polymers formed by bioconjugation of PEGylated nanoparticles are also shown to exhibit enhanced water solubility and stealth capabilities as drug delivery vehicles (Huang et al., 2022).

Interested in drug carriers? Our article on nanobody bioconjugation explains another application of anticancer drug carriers utilizing nanobodies.

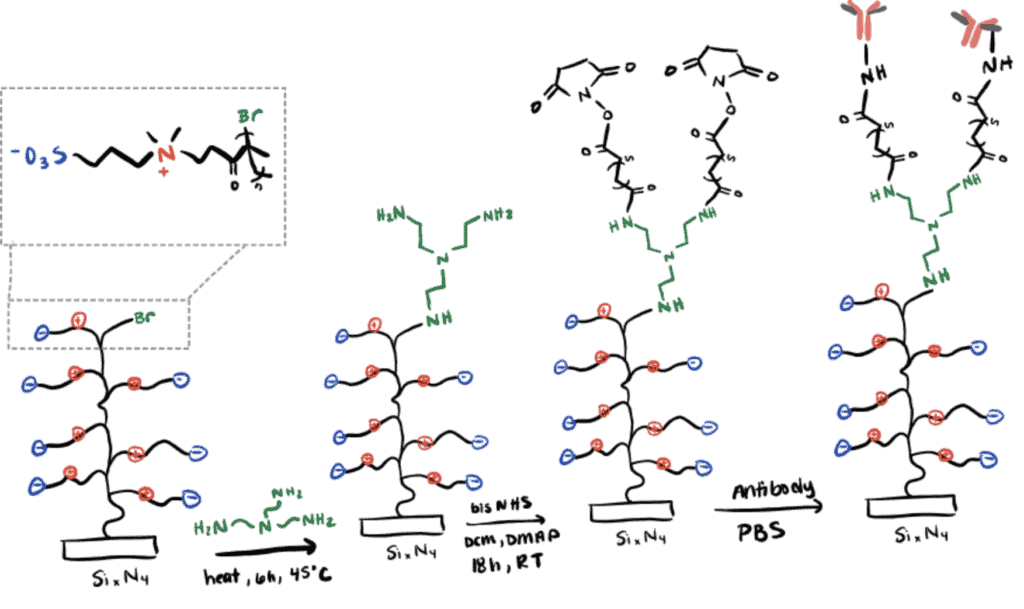

Application 2. Biosensing

Zwitterionic polymer brushes are identified as outstanding protein repellents. The conjugation of antibodies to zwitterionic polymers may result in improved specific detection of the target. The enhancement in specific detection is due to the prevention of nonspecific protein binding through properties of zwitterionic polymers.

In a study led by Nguyen et al., polySBMA brushes were grafted from silicon nitride surfaces via ATRP (Nguyen et al., 2012). Anti-Salmonella antibodies were immobilized onto the polySBMA brushes through NHS linkers. Data from fluorescent imaging showed that antibodies coated with polySBMA more efficiently captured Salmonella with low background noise compared to antibody-coated monolayers without the polymer brush. This study shows potential in zwitterionic layering in the prevention of nonspecific absorption to improve biosensing detection systems.

Application 3. Antifouling And Antimicrobial Surface Engineering

Biofouling, which is the attachment of unwanted proteins and macro-organisms on surfaces, can affect the functions and efficacies of various materials and structures. Polymer brushes with antimicrobial and antifouling properties can be tethered onto surfaces to reduce the consequences of biofouling.

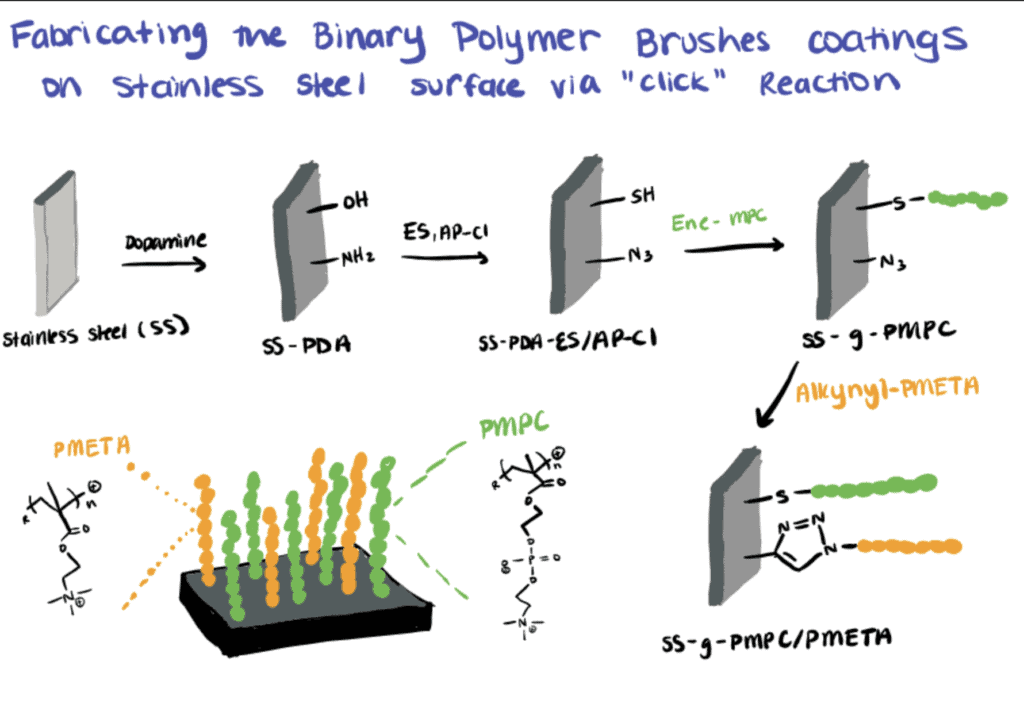

Similar to other azide bioconjugation reactions, Xu et al. demonstrated the assembly of binary polymer brushes PMPC and PMETA through thiol-ene and azide-alkyne “click” reactions, respectively (Xu et al., 2017). PMPC is a zwitterionic polymer that blocks protein adhesion, and PMETA is an antimicrobial cationic polymer brush. The binary functionalities of the resulting polymer brush resulted in improved overall antifouling and antimicrobial properties, compared to surfaces coated with only PMPC. This study is an example of how copolymer brushes can achieve advanced functionalities on a singular surface/ device.